Lithium-Ion technology is not new to the material handling market; however it is seeing increases in product offerings that support its superior battery technology to boost productivity across the supply chain. Lithium-Ion batteries are more environmentally friendly than lead-acid or other alternatives and offer higher energy densities which can lead to higher productivity.

Lithium-Ion technology stores more electricity for a longer period of time and is becoming standardized for most electric vehicles in this space. Lithium-Ion batteries are lightweight, allow for opportunity charging during shifts, are relatively maintenance free and do well in cold storage applications.

Benefits include:

Superior performance

Battery life has up to 4000 cycles and beyond

Fast charge completes in about two hours

Does not deplete battery “memory”

Consistent performance regardless of charge level

Single battery operation

Efficiency:

Eliminates the need for battery changes at each shift

Eliminates the need for battery watering

Lower total cost of ownership:

No daily maintenance

Saves space with no battery room required

Allows for smaller vehicles, maximizing warehouse space

Less wear on components

Sustainability:

Eliminates hazardous fumes or acid spills, making it more environmentally friendly

Lower carbon footprint

Increased recyclability

Energy Density

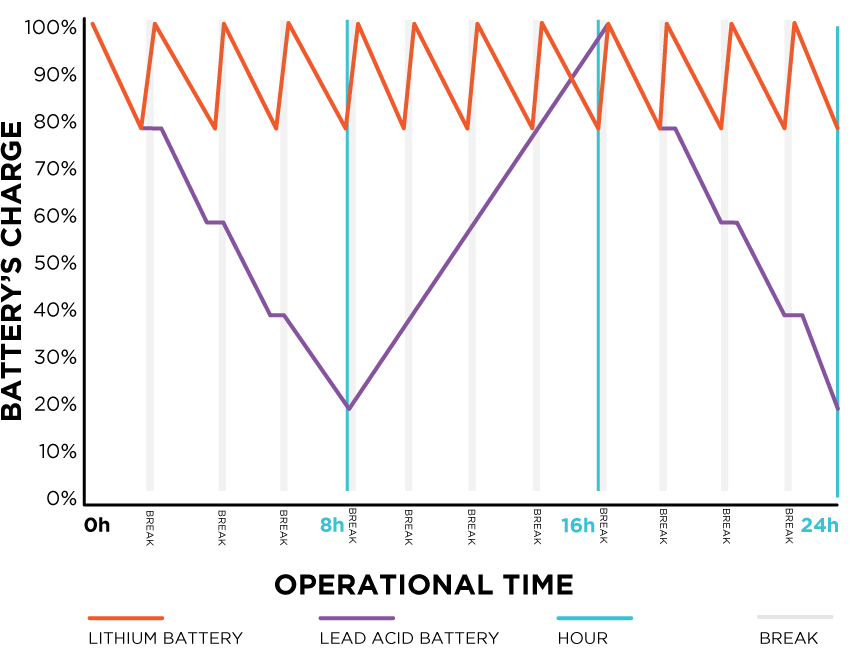

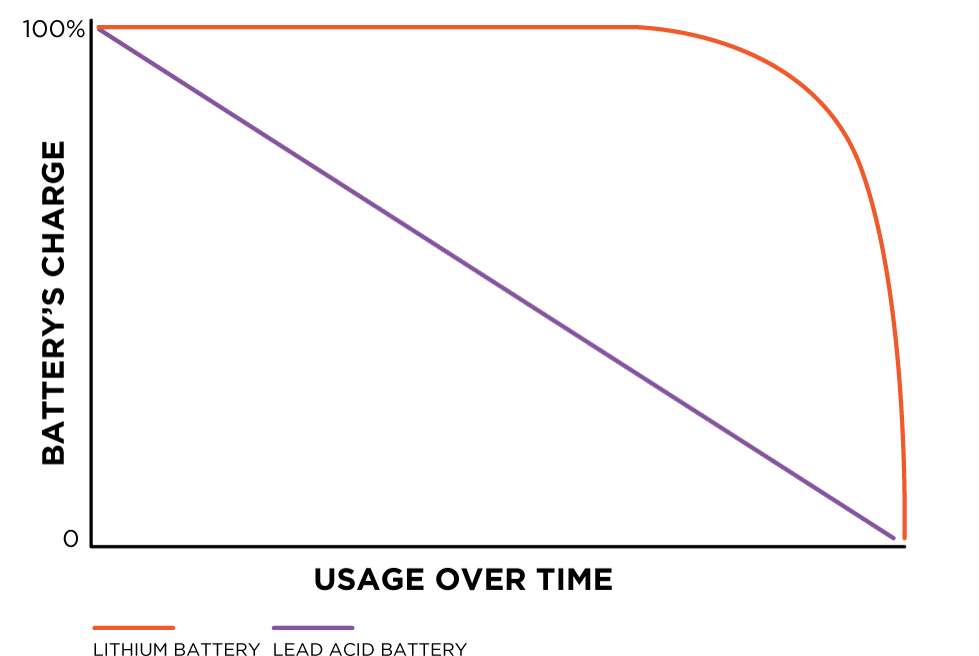

The Lithium-Ion battery packs can offer up to double the energy density of a lead-acid battery of similar size. The voltage supply is more stable throughout the energy discharge, allowing it to run at full capacity for longer.

Increased Safety

Cold Storage Use

Efficiency

Low Maintenance

Increased Safety

Lithium-Ion technology allows users to create, manage and maintain operations with significantly less down time, less warehouse and storage footprint and longer life-cycle of equipment. When managed properly, the introduction of Lithium-Ion batteries offer a lower total cost of ownership over time.

More Eco-Friendly

Longer Lifespan

Lithium-Ion batteries have a lifecycle of 4000 or more compared to just 500-1000 cycles in lead acid. Lithium-Ion batteries generally last for several times the number of cycles as lead acid batteries, leading to a longer effective lifespan for Lithium-Ion products. Cycles are also counted in percentage of charge rather than one cycle every time you connect the battery to the charger. This means: 10% charge is 1/10 of a cycle with a Li-Ion battery, while a 10% charge at a lead acid battery is one full cycle

Opportunity Charging

While lead acid battery's always need a full charge cycle of 8-12 hours to keep the batteries chemistry in balance, Lithium-Ion batteries really like opportunity charging. They can be plugged in the wall and charge for 10 minutes during a lunch break. This offers a unique way to work your shifts and reduce the overall Ah carried around in the truck.

Higher Efficiency

Faster Charging

High-efficiency batteries charge faster, improving capacity and overall performance. Lithium batteries take only 2-3 hours for a full charge, while lead-acid batteries need eight hours. As a result, Lithium batteries’ capacity reduces downtime in warehouse duties.

Is Every Lithium Battery the Same?

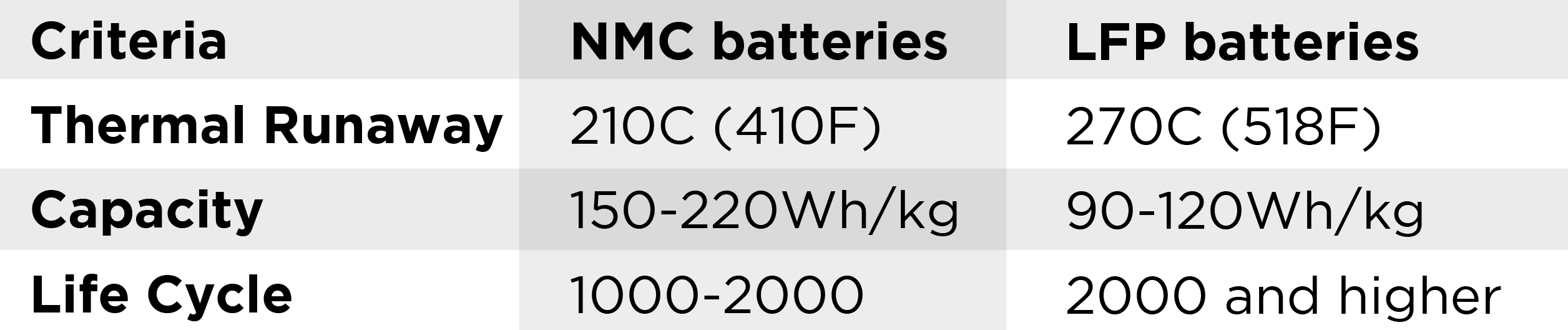

Lithium-Ion is named for its active materials. There are several types of chemical components to build rechargeable Lithium-Ion batteries. The most two relevant materials to the forklift industry are Lithium Iron Phosphate (LFP) and Lithium Nickel Manganese Cobalt Oxide (NMC).

NMC technology is very well known from the car industry and other manufacturing where weight and size play a major role. The upside of NMC batteries is a high energy density and the compact size. The downside of the NMC cell is the high possibility of inflammation and explosion when punctured or overheated. Due to the light weight and high energy density, some manufacturers are still using NMC in material handling products, while manufacturers like ePicker have switched to a different technology.

LFP technology is currently the technology used by the leading manufacturers of Li-Ion material handling products. LFP offers good electrochemical performance with low resistance. The key benefits are high current rating and long cycle life, besides good thermal stability, enhanced safety and tolerance if abused. There are many advantages to choosing a LFP-powered machine. Installed on larger equipment, like an electric node, pallet truck or forklift, the LFP battery does not catch fire or burn when punctured. LFP technology equals enhanced safety

Battery Life Over Charge

Charge Cycles Over Day